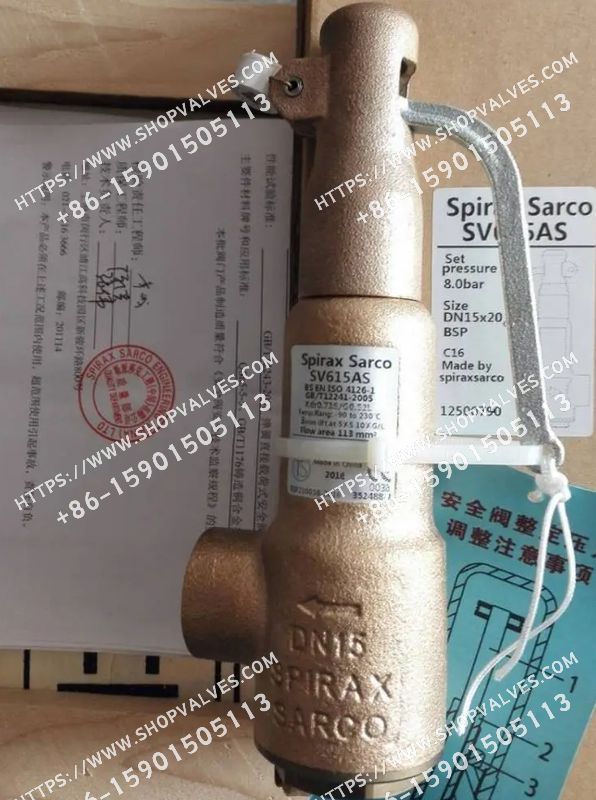

Spirax Sarco SV615/SV615AS Safety Valves

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Description

Spirax Sarco SV615 safety valves are full stroke, full nozzle safety valves for steam, air, non-chemical industrial gases and non-hazardous liquid applications. It can be used for the protection of equipment such as steam or hot water boilers, generators, pressure vessels and general steam, gas or liquid application scenarios.

Available Models

| Available types | SKU |

|---|---|

| 1/2" x 3/4" SV615 AS | tba |

| 3/4" x 1 1/4" SV615 AS | tba |

| 1" x 1 1/2" SV615 AS | tba |

| 1 1/4" x 2" SV615 AS | tba |

| 1 1/2" x 2 1/2" SV615 AS | tba |

| 2" x 3" SV615 AS | tba |

Caliber and connection

- caliber: DN15, DN20, DN25, DN32, DN40 and DN50.

- Inlet connection: BSP (BS 21) or NPT female thread; hygienic clamp connections (DN15, DN20 and DN25) to BS 4825/ISO 2852/DIN 32676 with 0.8um surface finish on the contact surface with the medium.

- outlet connection: BSP (BS 21) or NPT female thread.

Available Models

Bore sizes from DN15 to DN50, bronze bodies with female threaded connections and stainless steel nozzles. Smaller bore models are available with sanitary clamp connections. All safety valves are available with closed bonnets with simple microlift levers or closed bonnets (gas-tight end cap option). Nitrile, EPDM, or Viton soft-seal options are available. Non-electrolytic nickel plated (ENP) polished finishes for the body, microlift stem cavity (or sealed bonnet), and microlift stem are available, as well as stainless steel nameplates.

Standards and certifications

Fully compliant with EN ISO 4126:2004 and marked to comply with the European Pressure Equipment Directive (PED) 97/23/EC, certified by SAFed TAS. seat sealing performance in accordance with ANSI/API STD 527 - 1992.

Certification

Each safety valve is supplied with a certificate according to EN 10204 2.2, including valve set pressure and liquid test pressure. Material certificates according to EN 10204 3.1 are available on request.

Pressure/Temperature Limits

- Valve body design conditions: PN25.

- Setting pressure range: Minimum 0.3 bar g, maximum 18 bar g for ½" - 1¼", 14 bar g for 1½" and 2".

- temperature limitMetal seat min -90°C, max +230°C; Buna-N seals min -30°C, max +150°C; EPDM seals min -50°C, max +200°C; Fluorinated rubber seals min -20°C, max +120°C.

- Over Pressure: 51 TP3T for vapors, 10 - 251 TP3T for liquids and gases.

- opening and closing differential pressure: Vapors, gases 2.5 - 20%, liquids 10%.

- Maximum permissible back pressure: 37.5 bar g.

material (that sth is made of)

| Item | Part | material (that sth is made of) |

|---|---|---|

| 1 | valve body | Bronze, BS EN 1982 CC491KM |

| 2 | extrusion nozzle | DN15 and DN20 stainless steel, BS 970 431 S29; DN25 - DN50 stainless steel, BS 3146 Pt2 Gr. ANC2; clamp connections stainless steel, ASTM A276 316L |

| 3 | compact disc | Stainless Steel, ASTM A276 316L |

| 4 | microliter cavity | Bronze, BS EN 1982 CC491KM |

| 5 | sprung | Chrome vanadium alloy steel, BS 2803 735 A50 HS |

| 6 | Spindle guide | Brass, BS 2872 CZ 121 |

| 7 | Spring-loaded top plate | Brass, BS 2872 CZ 121 |

| 8 | principal axis (in mechanics, optics, botany etc) | Stainless steel, BS 970 431 S29 |

| 9 | adjusting screw | Brass, BS 2874 CZ 121 |

| 10 | microlift lever | Ductile iron, Zinc plated |

| 11 | plunger pin | Stainless steel, AISI 304 |

| 12 | spring ring | Stainless steel, BS 2056 316 S42 |

| 13 | Adjusting handle locking nut | Brass, BS 2872 CZ 121 |

| 14 | Soft Seal Discs | Stainless Steel/NBR, ASTM A276 316; Stainless Steel/EPDM, ASTM A276 316; Stainless Steel/Fluorinated Rubber, ASTM A276 316 |

| 15 | airtight end caps | Bronze, BS EN 1982 CC491KM |

| 16 | Bonnet Seal | nitrile rubber |

| 17 | outer edge | Brass, BS 2874 CZ 121 |

| 18 | set screw | steel (chemistry) |

| 19 | sphere | stainless steels |

Displacement data

- Saturated steam displacement (kg/h): (Calculated according to EN ISO 4126: 2004, 5% over pressure, rated displacement coefficient ((Kdr)=0.71)), different valve sizes and set pressures have different values of displacement, e.g. DN15/20 at a set pressure of 0.5 bar g with a displacement of 1.0 kg/h, DN20/32 at a set pressure of 1.0 bar g with a displacement of 95 kg /h, etc.

- Air displacement (l/s): (15°C and 1.013 bar a, calculated according to EN ISO 4126: 2004, 10% over pressure, rated displacement coefficient ((Kdr)=0.71)), with different values of displacement for different valve sizes and set pressures, e.g. 24l/s for DN15/20 at a set pressure of 0.5bar g, DN20/32 at a set pressure of For example, DN15/20 has a displacement of 24l/s at a set pressure of 0.5bar g, DN20/32 has a displacement of 91l/s at a set pressure of 1.0bar g, etc.

- Water discharge (kg/h)(20°C, calculated according to EN ISO 4126: 2004, 10% over pressure, rated displacement coefficient ((Kdr)=0.52)), different valve sizes and set pressure have different values of displacement, such as DN15/20 at a set pressure of 0.5 bar g displacement of 2216kg/h, DN20/32 at a set pressure of 1.0 bar g DN20/32 at a set pressure of 1.0 bar g, the displacement is 8710kg/h, and so on.

- Hot water discharge (kW): (greater than or equal to 100°C, calculated according to EN ISO 4126: 2004, rated displacement coefficient ((Kdr)=0.52)), different values of displacement for different valve sizes and set pressures, e.g. DN15/20 displacement at set pressure 0.5 bar g is 29.96kW, DN20/32 displacement at set pressure 1.0 bar g is 112.81kW, etc.

weights

| grout | caliber | Weight (kg) |

|---|---|---|

| Threaded connection BSPF x BSPF or NPTF x NPTF | DN15 | 1.3 |

| Threaded connection BSPF x BSPF or NPTF x NPTF | DN20 | 2.4 |

| Threaded connection BSPF x BSPF or NPTF x NPTF | DN25 | 2.9 |

| Threaded connection BSPF x BSPF or NPTF x NPTF | DN32 | 4.2 |

| Threaded connection BSPF x BSPF or NPTF x NPTF | DN40 | 8.8 |

| Threaded connection BSPF x BSPF or NPTF x NPTF | DN50 | 13.0 |

| Hygienic clamp connections | DN15 | 1.4 |

| Hygienic clamp connections | DN20 | 2.6 |

| Hygienic clamp connections | DN25 | 3.1 |

Installation Notes

Installation should ensure that the centerline of the spring chamber of the safety valve is vertically upward.

Selection instructions

- screw connectionModel SV615 is available in closed bonnet/microlift stem (A) and closed bonnet/gas-tight end cap (B); polished in electroless nickel plating (ENP) (P), electroless nickel plating, and stainless steel nameplate (Q); sizes in DN15, DN20, DN25, DN32, DN40, and DN50; and connections (inlet and outlet) in BSPF x BSPF, NPTF x NPTF, Clamp x BSPF.

- Hygienic clamp connectionsThe same is true for the corresponding models, shapes, finishes, calibers and other options.

Selection Examples

If an ELNP polish is required, add 'P' e.g. DN15 BSPF x BSPF.

How to Order

Example: 1 - Spirax Sarco SV615AN DN15 BSP threaded connection safety valve with 6 bar g set pressure.