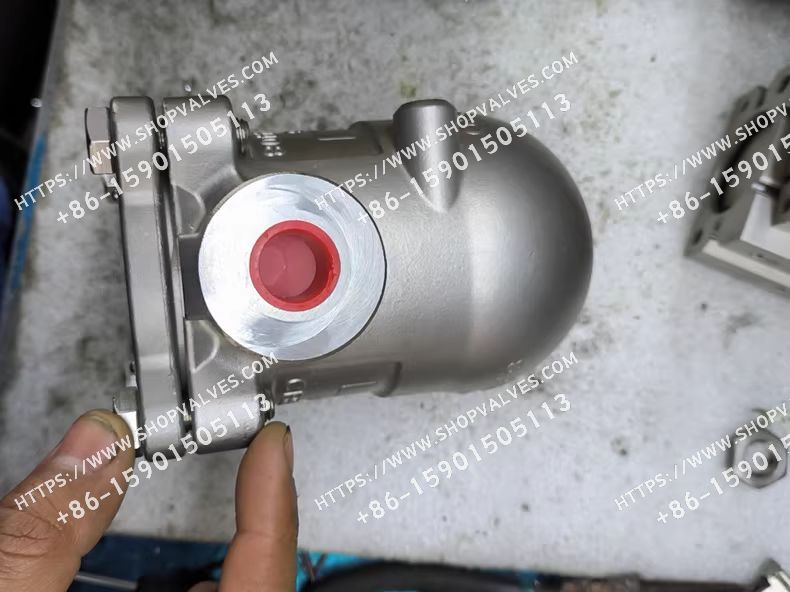

Spirax Sarco FTS14 Austenitic Stainless Steel Ball Float Steam Trap

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Description

The Spirax Sarco FTS14 austenitic stainless steel float steam trap with built-in automatic air venting valve effectively removes condensate and removes air, ensuring that process equipment operates at maximum efficiency. The standard FTS14 is installed horizontally with a right-to-left flow direction (R-L), and can be converted to a left-to-right installation (L-R) or a vertical installation with an upward or downward flow direction by simply rotating the bonnet.

Standards and Certificates

- Complies with the European Pressure Equipment Directive 97/23/EC.

- EN 10204 3.1 certificate available (to be specified when ordering).

Sizes and pipe connections

| caliber | connection method |

|---|---|

| ½", ¾" and 1". | Screwed BSP (BS 21 and DIN 2999) or NPT (ANSI B 1.20.1); socket welded (ANSI B 16.11, BS 3799 Class 3000 and DIN 3239); sanitary clamp connections |

| DN 15, 20 and 25 | Flanges ANSI B 16.5 150Lb and 300Lb or EN 1092/PN16/25 |

selectable

- With built-in filter (FTS14X).

- Add a manually adjustable needle valve as an anti-steam vapor lock device (FTS14-C).

- The bonnet can be drilled with 1/8" BSP threaded holes for mounting a temperature sensor (all options available at additional cost).

Limitations (ISO 6552)

| Valve body design conditions | PN25 |

|---|---|

| PMA - Maximum Allowable Pressure | 25 bar g |

| TMA - Maximum Allowable Temperature | 300 °C |

| TMO - maximum operating temperature | 225 °C |

| Minimum working temperature | -20 °C (for lower operating temperatures, consult Spirax Sarco) |

| Maximum cold hydrostatic test pressure | 37.5 bar g |

| Note: For sanitary clamp connections, the maximum pressure and temperature limits should be determined by the gasket and clamp used. |

material (that sth is made of)

| Item | parts | material (that sth is made of) |

|---|---|---|

| 1 | valve body | Austenitic stainless steel (316) EN 10213-4(1.4408) ASTM A351 CF8M |

| 2 | Bonnet bolts | Stainless steel BS EN 3506 A2-70 |

| 3 | Bonnet Gasket | Reinforced flake graphite |

| 4 | bonnets | Austenitic stainless steel (316) EN 10213-4(1.4408) ASTM A351 CF8M |

| 5 | Main valve seat | Stainless steel BS 970 431 S29 |

| 6 | Main Valve/Vent Valve Seat Gasket | stainless steels |

| 7 | Main valve assembly screws | stainless steels |

| 8 | Float ball linkage | Stainless steel BS 1449 304 S16 |

| 9 | Air venting valve unit | stainless steels |

| 10 | SLR unit | stainless steels |

| 11 | SLR Gasket | stainless steels |

| 12 | Pivot bracket | stainless steels |

| 13 | SLR Seal | plumbago |

| 14 | fulcrum | stainless steels |

| 15 | O-ring | Gray Viton Compliant T21,P177,S2600 FDA CFR |

| *16 | Main valve spring (1" only) | stainless steels |

| *17 | inductor plug | Stainless steel (optional) |

| *18 | filter | Stainless steel (optional) |

∆PMX - Maximum Differential Pressure

| Available types | Maximum differential pressure |

|---|---|

| FTS14-4.5 | 4.5 bar |

| FTS14-10 | 10 bar |

| FTS14-14 | 14 bar |

Security information, installation and maintenance

See the Installation and Maintenance Guide (IM-P145-02) supplied with the product for details.

Ordering Instructions

Example: 1 - Spirax Sarco ½" FTS14X-4.5 R-L steam trap in stainless steel with BSP threaded connection. Trap is in-line serviceable with built-in air vent and built-in strainer. 1/8" threaded holes can be drilled for temperature sensor installation at additional cost.