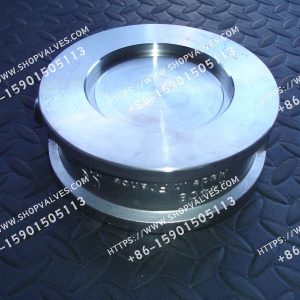

Spirax Sarco CVS10-1M Clean Metal Seat Check Valve

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Description

Spirax Sarco CVS10 Clean Metal Seat Check Valves are spring-loaded, clean check valves manufactured in 316L stainless steel, designed to prevent backflow of fluids in pipelines. This metal-seated product is widely used in the food, pharmaceutical and medical industries, primarily for steam and other harsh environments where soft seats are not suitable. EPDM, Viton and FEP - Silicon soft seal seats are available for water, process and gas applications (see TI - P029 - 10 for details). Different surface finishes are available, such as CVS10-1 polished to 0.5 micron Ra (in accordance with ASME BPE SF1) on the inner surface and 0.8 micron Ra on the outer surface, and CVS10-2 electropolished to 0.38 micron Ra (in accordance with ASME BPE SF4) on the inner surface and 0.8 micron Ra on the outer surface.

(an official) standard

- The CVS10 is fully compliant with the European Pressure Directive 97/23/EC.

- CVS10 designed to meet ASME BPE standards

Shutdown Criteria

Metal-seated CVS10 shut-off according to EN 12266 - 1:2003 Rate D

Certification

- EN 10204 3.1 Material certificate

- Typical Surface Polishing Certificate (Note: If a certificate or inspection is required please specify when ordering)

wrap

The product is isolated from other non-stainless steel products and packaged separately in a clean environment. In accordance with ASME BPE standards, the inlet and outlet connection ends are sealed with caps, and the entire valve is sealed in a plastic bag to avoid dust ingress.

material (that sth is made of)

| Item | Part | makings |

|---|---|---|

| 1 | valve body | 316L stainless steel |

| 2 | cone | 316L stainless steel |

| 3 | sprung | 316 stainless steel |

Caliber and connecting pipe

½", ¾", 1", 1 - ½" and 2" ASME BPE sanitary clamps, DN15 to DN50 DIN 32676 sanitary clamps (other connections, diameters and cracking pressures are available upon request)

Pressure/Temperature Limits

Areas exist where the product cannot be used.

| Valve body design conditions | PN10 |

|---|---|

| PMA Maximum Allowable Pressure | 10bar@200℃ |

| TMA Maximum Allowable Temperature | 220°C@10.5barg |

| Minimum permissible temperature | -254°C |

| PMO Saturated Steam Maximum Working Pressure | 10barg |

| TMO Maximum Operating Temperature | 220°C@10barg |

| Minimum working temperature | 0°C |

| Design maximum cold hydrostatic test | 15barg |

weights

| caliber | Weight (kg) |

|---|---|

| ½" | 0.10 |

| ¾" | 0.10 |

| 1" | 0.15 |

| 1 - ½" | 0.18 |

| 2" | 0.35 |

Kv value

| caliber | ½" | ¾" | 1" | 1 - ½" | 2" |

|---|---|---|---|---|---|

| Kv | 2 | 2 | 4 | 8 | 18 |

Conversion formula: Cv(UK)=Kv×0.963, Cv(US)=Kv×1.156

Opening pressure (mbar)

| caliber | ½" | ¾" | 1" | 1 - ½" | 2" |

|---|---|---|---|---|---|

| Cracking Pressure | 35, 39, 31 | 35, 39, 31 | 35, 39, 31 | 35, 39, 31 | 35, 39, 31 |

(of a computer) run

The valve opens by fluid pressure. When the fluid stops flowing, the spring closes the valve before the fluid flows backwards.

Security information, installation and maintenance

See the Installation and Maintenance Guide (IM - P029 - 11) supplied with the product for details.

place an order

Example: A set of CVS10 - 1 clean-type check valves with metal seats, ASME BPE sanitary clamp connections, and polished internal surfaces to an accuracy of 0.5 micron Ra (20 micro inches), with complete certification information provided.