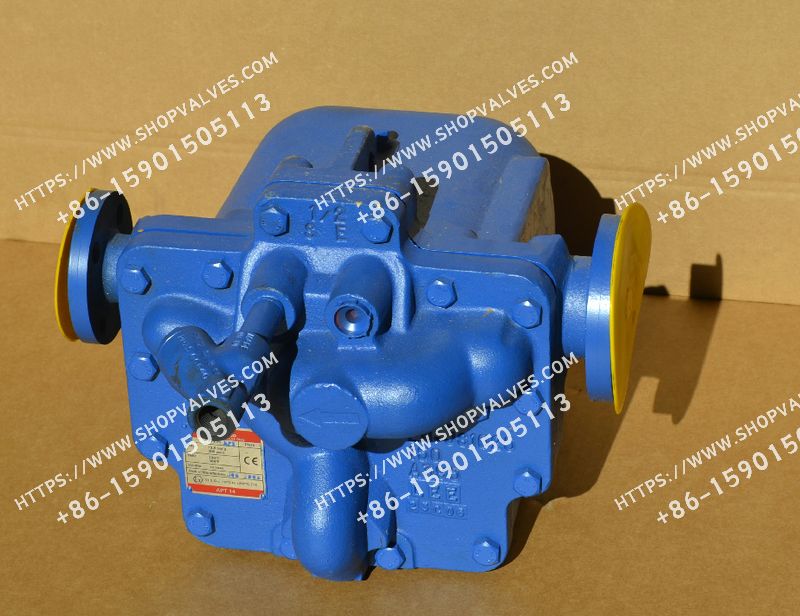

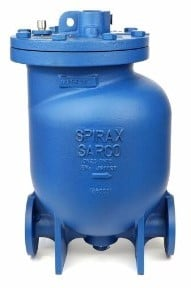

Spirax Sarco APT14/APT14HC/APT14SHC Automatic Trap Pumps

Brand authorization

- Rapid response service

- Professional team support

- Flexible return and exchange policy

Description

Spirax Sarco APT14, APT14HC and APT14SHC automatic trap pumps with a pressure rating of PN16 are available in both flanged and threaded connections. The unit automatically switches between trap cycling and pump cycling depending on the pressure in the line. Using steam as the motive force, condensate can be removed from process equipment under any operating conditions, including vacuum.

Standards and Certificates

- The pump body is designed to meet A.D. Merkblatter/ASME VIII standards.

- Complies with European Pressure Equipment Directive 97/23/EC, ATEX Directive 94/9/EC, relevant markings available on request.

- This product can be supplied with an EN 10204 3.1 certificate, if a certificate is required, please specify when ordering.

weights

| Available types | connection method | weights |

|---|---|---|

| APT14 | screw connection | 45kg |

| APT14 | flange connection | 45kg |

| APT14HC | flange connection | 65kg |

| APT14SHC | flange connection | 105kg |

Component Material

| Item | Part | APT14 material | APT14HC Material | APT14SHC Material |

|---|---|---|---|---|

| 1 | pump cover | Ductile iron (EN JS 1025 or ASTM A395) | Ductile iron (EN JS 1025 or ASTM A395) | Carbon steel (EN 1.0619+N or ASTM A216 WCB) |

| 2 | Pump cover gasket | Stainless steel reinforced with laminated graphite | Stainless steel reinforced with laminated graphite | Stainless steel reinforced with laminated graphite |

| 3 | pump body | Ductile iron (EN JS 1025 or ASTM A395) | Ductile iron (EN JS 1025 or ASTM A395) | Carbon steel (EN 1.0619+N or ASTM A216 WCB) |

| 4 | Pump cover bolts | Stainless steel (ISO 3506 Gr. A2 70) | Stainless steel (ISO 3506 Gr. A2 70) | Stainless steel (ISO 3506 Gr. A2 70) |

| 5 | pump connecting rod | Stainless steel (BS 1449 304 S15) | Stainless steel (BS 1449 304 S15) | Stainless steel (BS 1449 304 S15) |

| 6 | float | Stainless steel (BS 1449 304 S15) | Stainless steel (BS 1449 304 S15) | Stainless steel (BS 1449 304 S15) |

| 7 | Trap Linkage | Stainless steel (BS 1449 304 S15) | Stainless steel (BS 1449 304 S15) | Stainless steel (BS 1449 304 S15) |

| 8 | Second Stage Trap | Stainless Steel (ASTM A276 440 B) | Stainless Steel (ASTM A276 440 B) | Stainless Steel (ASTM A276 440 B) |

| 9 | trap chamber | Stainless steel (BS 3146 ANC 2) | Stainless steel (BS 3146 ANC 2) | Stainless steel (BS 3146 ANC 2) |

| 10 | spool | Stainless Steel (ASTM A276 440 B) | - | - |

| 11 | Valve seat (inlet check valve) | Stainless steel (AISI 420) | Stainless steel (AISI 420) | Stainless steel (AISI 420) |

| 12 | Flapper (inlet check valve) | Stainless steel (BS 3146 ANC 4B) | Stainless steel (BS 3146 ANC 4B) | Stainless steel (BS 3146 ANC 4B) |

| 13 | Pump Mechanism Bracket | Stainless steel (BS 3146 ANC 4B) | Stainless steel (BS 3146 ANC 4B) | Stainless steel (BS 3146 ANC 4B) |

| 14 | Spring (pump) | Stainless steel (BS 2056 302 S26 Gr. 2) | Stainless steel (BS 2056 302 S26 Gr. 2) | Stainless steel (BS 2056 302 S26 Gr. 2) |

| 15 | cotter pin | Stainless steel (BS 1574) | Stainless steel (BS 1574) | Stainless steel (BS 1574) |

| 16 | Exhaust Valve Seat | Stainless steel (BS 970 431 S29 or ASTM A276 431) | Stainless steel (BS 970 431 S29 or ASTM A276 431) | Stainless steel (BS 970 431 S29 or ASTM A276 431) |

| 17 | Inlet spool and seat unit | stainless steels | stainless steels | stainless steels |

| 18 | Exhaust Valve Spool | Stainless steel (BS 3146 ANC 2) | Stainless steel (BS 3146 ANC 2) | Stainless steel (BS 3146 ANC 2) |

| 19 | Seat Gasket | Stainless steel (BS 1449 409 S19) | Stainless steel (BS 1449 409 S19) | Stainless steel (BS 1449 409 S19) |

| 20 | Pump mechanism bolts | Stainless steel (ISO 3506 Gr. A2 70) | Stainless steel (ISO 3506 Gr. A2 70) | Stainless steel (ISO 3506 Gr. A2 70) |

| 21 | Trap cover bolts | Stainless steel (BS 6105 A4 80) | Stainless steel (BS 6105 A4 80) | Stainless steel (BS 6105 A4 80) |

| 22 | First Stage Trap | Stainless steel (BS 970 431 S29 or ASTM A276 431) | Stainless steel (BS 970 431 S29 or ASTM A276 431) | Stainless steel (BS 970 431 S29 or ASTM A276 431) |

| 23 | 'O' ring | EPDM | EPDM | EPDM |

| 24 | push rod or tappet (mechanics) | Stainless steel (BS 3146 ANC 2) | Stainless steel (BS 3146 ANC 2) | Stainless steel (BS 3146 ANC 2) |

| 25 | nameplate | Stainless steel (BS 1449 304 S16) | Stainless steel (BS 1449 304 S16) | Stainless steel (BS 1449 304 S16) |

| 26 | plug | Steel (DIN 17440 1.4571) | Steel (DIN 17440 1.4571) | Steel (DIN 17440 1.4571) |

| 27 | Inlet Valve Spring | stainless steels | stainless steels | stainless steels |

| 28 | Filter Inlet Valve | ductile iron | ductile iron | carbon steel |

| 29 | Check Valve DCV (APT14HC) | Stainless steel (not shown) | Stainless steel (not shown) | - |

Pressure/Temperature Limits

| Valve body design conditions | PN16 |

|---|---|

| Maximum Power Steam Inlet Pressure | 13.8 bar g |

| PMA Maximum Allowable Pressure | 16 bar g @ 120°C |

| TMA Maximum Allowable Temperature | 300°C @ 12.8 bar g |

| Minimum permissible temperature | -10°C |

| PMO Saturated Steam Maximum Working Pressure | 13.8 bar g @ 198°C |

| Maximum back pressure | 5 bar g |

| TMO Saturated Steam Maximum Operating Temperature | 198°C @ 13.8 bar g |

| Minimum working temperature | -10°C |

| Temperature (ambient) | -10°C - 200°C |

| Design maximum cold hydraulic test pressure | 24 bar g |

Mounting Height

| Mounting height type | high degree |

|---|---|

| Recommended mounting height (from pump base) | 0.3 m |

| Recommended maximum mounting height (from pump base), consult Spirax Sarco for higher mounting heights. | 1 m |

| Minimum mounting height (from pump base) | 0.2 m |

Nominal Displacement

| Available types | APT14 | APT14HC and APT14SHC |

|---|---|---|

| Pump Displacement/Cycle | 5 liters | 8 liters |

| 1 m installation height, 5 bar g power steam, 1 bar g back pressure | Maximum hydrophobic mode discharge 4000kg/h, maximum pump mode discharge 1100kg/h | Maximum hydrophobic mode displacement 9000kg/h, maximum pump mode displacement 2800kg/h |

Note: The above table shows the discharge capacity of automatic trap pumps under specific installation conditions, as shown in the first column on the left side of the table. For different installation conditions and parameters, the discharge capacity of automatic trap pumps may change. Please consult Spirax Sarco for specific applications and discharge capacities. In order to achieve the calibrated discharge capacity, the total lift or back pressure BP (hydrostatic head plus pressure in the condensate line) of the automatic trap must be lower than the pressure of the motive steam.

Height (H)m x 0.0981 + Pressure in condensate piping §bar g + Flow friction resistance in downstream piping (Pf) bar. (If the distance of the downstream piping is less than 100 mm and the condensate piping is a non-diffusible pipe, and if the effect of flash steam under the maximum heat exchanger operating load has been taken into account in piping sizing, the piping flow friction resistance Pf can be ignored.)

Product Description

- APT14 and APT14HC: Maximum steam working pressure of 13.8 bar g without any electrical power. The pump body is made of ductile iron (EN JS 1025 or ASTM A395). The inlet is equipped with a swing check valve and the APT14 outlet with a ball check valve. The built-in trap mechanism consists of two stainless steel floats and a two-stage trap; the built-in pump mechanism is a stainless steel spring-loaded quick-action mechanism with no external seals or packings.

- APT14SHC: Maximum steam working pressure of 13.8 bar g without any electrical power. The pump body material is carbon steel (EN 1.0619 or ASTM A216 WCB). The inlet is equipped with a swing check valve, the built-in trap mechanism consists of two stainless steel floats and a two-stage trap; the built-in pump mechanism is a stainless steel spring-loaded quick-action mechanism with no external seals or packings.

Ordering Instructions

Example: 1 - Spirax Sarco automatic trap pump APT14, DN40 x DN25, flange connection EN1092 PN16, with threaded connection BSP power steam connection.

How to order

The availability of spare parts is indicated by solid lines in the relevant information and dotted lines are not provided as spare parts. Spare parts are supplied in sets to ensure that all parts required for repair are included. For example, when ordering an inlet/exhaust spool valve seat assembly, cotter pins, gaskets, and shims are supplied in addition to the major components required for service.

Order spare parts

Please order spare parts as described above, specifying the type and size of the automatic trap pump. Example: 1 - Steam inlet/outlet spool valve seat assembly for Spirax Sarco APT14 DN40 x DN25 automatic trap pumps. For Spirax Sarco APT14 DN40 x DN25 automatic trap pumps.